Fox Valley Spring

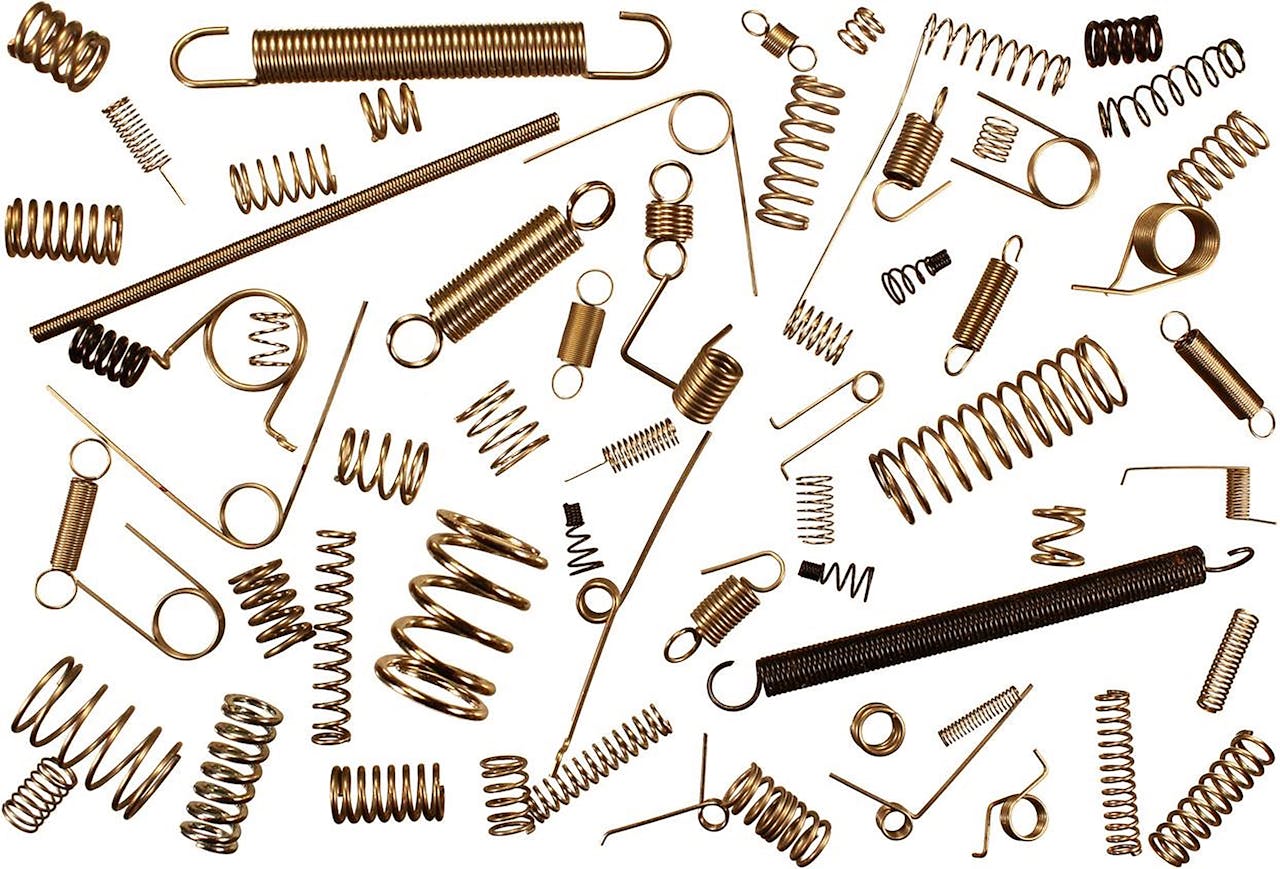

Springs, Wire Forms, and Flat Springs

When you partner with Fox Valley Spring, you will experience benefits such as our 10-piece minimum order, in-house design support, flexible stocking programs, 24-hour quote response, competitive production lead times, and unparalleled customer service.

Have questions or need a custom quote? Contact us. Someone will be in touch in 24 hours or less.

Who We Are

With our automated computer-controlled spring coilers, we manufacture complex springs for any application. Fox Valley has been manufacturing springs since 1989 in our state-of-the-art 78,000 square foot facility in Greenville (Appleton), Wisconsin. As a locally run facility that's part of a nationwide manufacturing enterprise, MW Components, we are uniquely positioned to provide the personalized service of a small company along with the support of a large business.

Whether you are looking for compression springs, extension springs, torsion springs, wire forms, die springs, flat steel or a custom-made spring, Fox Valley is your best choice.

If you're already a customer - thank you! We strive to provide the highest quality products and the best customer service. Tell us how we're doing by filling out our customer survey: Fox Valley Customer Opinion Survey

Our Products

-

We manufacture custom compression springs from 0.006" to 0.625" wire in a wide variety of standard and exotic materials.

-

We produce custom extension springs from 0.008" to 0.375" wire in several materials, including stainless steel and exotic alloys.

-

Our torsion spring manufacturing supports 0.008" to 0.250" wire in carbon steels and exotic alloys.

-

Our wire form manufacturing supports 0.008" to 0.200" wire diameters. Should you have a special request, we can manufacture up to 0.500" diameter wire forms.

-

We manufacture constant force springs as a rolled ribbon that allows the spring to relax when fully rolled up.

-

Flat springs are a custom part that are manufactured from tooling integrated into progressive die or fourslide equipment.

See Our Facility

We're proud of our facility and the expert team that produces your products. Take a video tour to learn more about our capabilities, products, and services.

Want to see what we can do in person? Come visit us in Greenville, Wisconsin. We'll be happy to show you around. Contact us to schedule an in-person tour.

Tell Us How We Did: Take Our Customer Survey

We have a nationwide reputation for providing some of the best support in the industry, but we know our past performance isn't enough. We need to continue to improve and adjust so we can meet the needs of our customers now and in the future.

Your feedback is what makes that possible. If you're a current or past customer, we'd like to hear from you. Take the survey to tell us how we did - and how we can do better.